Order process automation is one of the most popular solutions in the age of digital transformation. Manufacturing companies are facing big challenges trying to meet the market’s demand and keeping their position as leaders in the industry. Product configurator is a great solution for those struggling with a limited product offer despite much larger resources as well as those who are looking for ways to reduce operational costs.

1. What is order process automation?

A traditional approach to order fulfilment process usually consist of a salesperson, customer service, the ERP system and a handful of employees responsible for manufacturing. Thanks to the newest technical solutions we’re able to streamline the process, speed up the delivery time and reduce resources.

Order process automation is a category of tech solutions that aim to minimize human involvement in the process. It can be achieved by using Internet of Things solutions, artificial intelligence, machine learning and even web development combined with a lot of business knowledge. And this last approach is what we’re going to focus on in this article.

2. Product configurator for an order process automation

Many companies don’t invest in extensive IoT solutions due to lack of necessary resources or budget. However, there’s a perfect middle ground solution that will give us the automation that we need using only web development.

One of extremely profitable solutions, especially for manufacturing industry is product configurator for process automation.

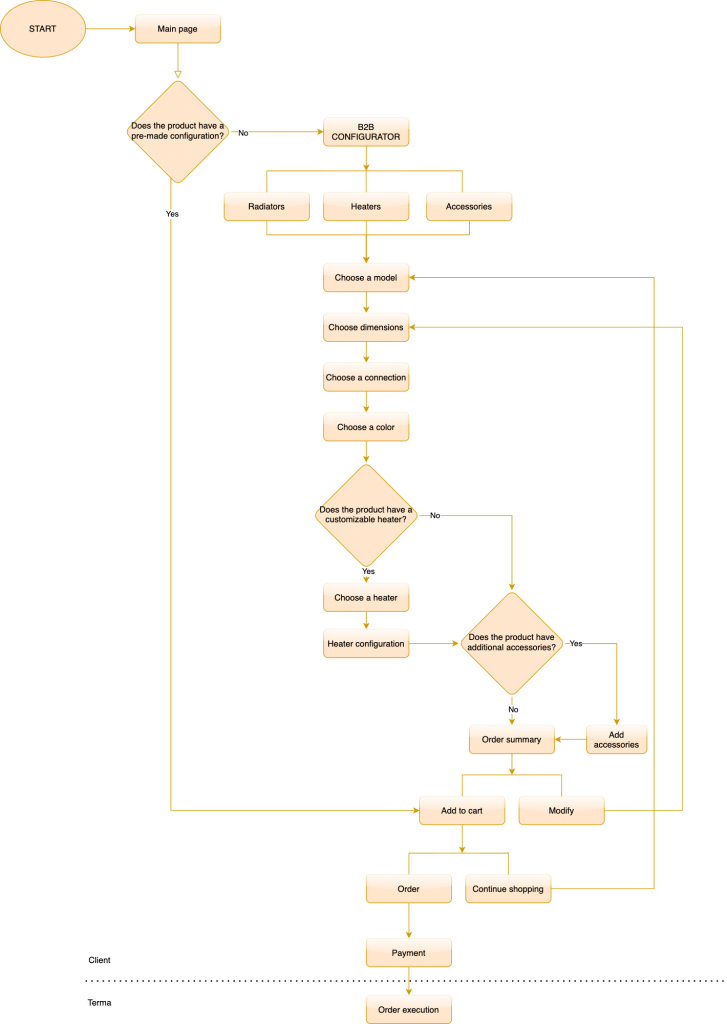

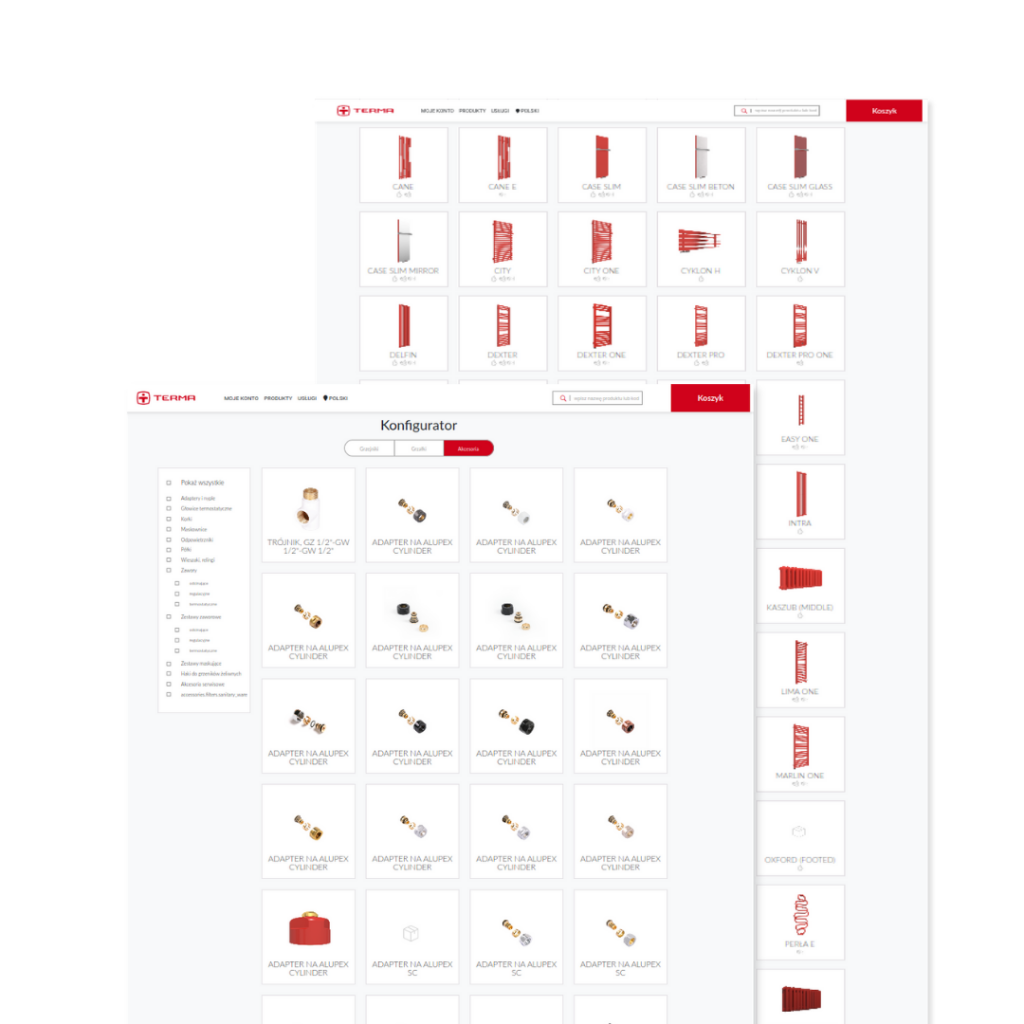

One of our projects was developing a product configurator for B2B radiator manufacturer. We integrated the solution into the client’s e-commerce system and the ERP system. It gave us the opportunity to implement the necessary automation features.

3. Product configurator integrated with the ERP system

A simple b2b product configurator doesn’t have a lot of power to automate internal processes. However, we can change that by integrating the solution into the ERP system.

ERP is responsible for managing internal processes that are taking place in the company. It collects, stores and manages data to make the business more efficient. We can use it to make our product configurator more powerful.

How much time does your staff waste on typing in the order details into the system? Or how many times does the customer have to contact you before the order is confirmed? All of these processes can be automated and that’s exactly what many businesses have been doing.

4. Benefits of product configurator solution

The benefits of b2b product configurator solution are significant to both the business and the client. This implementation is a step forward towards modern manufacturing. Here’s what you can achieve with this type of project:

– Full product offer available on one platform

One of the issues a manufacturing company faces is the lack of infrastructure that allows presenting all variations of the product. Usually machines can be set to produce a variety of configurations.

The problem here is the difficulty to showcase all of the options to the customer. That’s where product configurator comes in. It provides the information on all of the possible settings so the customer can choose from the full range of options.

– Automatic validation of the product configuration by the application

There’s nothing worse than having thousands of possible product variations and not knowing which are correct. This causes a need for Customer Service to contact the manufacturing department. It extends the time of the ordering process, the customer has to wait and the employees are spending extra time validating each order. But not with product configurator.

The application can automatically validate each order as it’s being created. It limits the unnecessary customer-vendor interaction.

– Human factor is minimized

A big part of company’s expenses are the employees salaries. We can limit these expenses by minimizing human involvement in the ordering process. We can also move the resources to other departments where they’re most needed.

It also gives the customer the comfort of ordering the products faster and without having to contact the Customer Service.

– Transfer of a correctly added and paid order directly to the production

Here’s another part of the automation – the transfer of a correctly configured order directly to production. By integration with the ERP system we’re able to create a connection between the product configurator and the production.

The manufacturing receives not only the order details but also the required product configuration. It automatically sets up the machine to manufacture this exact product configuration.

– An extra sales channel for the business

Last but not least, product configurator gives the business and extra profit. It can reach new clients and become another sales channel. This form of making a purchase has become a lot more popular. Customers are looking for unique products that will satisfy their needs.

5. Why is the manual sales process not enough?

We’ve come to the point where digital leadership is the key factor that determines company’s future. Innovative brands are the ones influencing the market. That’s why so many businesses consider implementing automation.

Here’s an infographic that shows that over 20% of warehouse facilities already have some form of automation. Another 50% is planning on implementing this type of a solution within the next 5 years.

Summary

It’s always better to discuss solutions based on an actual example and the real data. So if you’re interested in learning more – check out our newest case study on product configurator for the radiator manufacturer.

Implementing automation technology is not a matter of IF, it’s a matter of WHEN.

We also recommend:

- BoostHigh as Top Software Development Provider in Poland!

- Fixed Price vs. Time & Material in Software Development

- Surveillance System Software For Public Transport – Case Study

- B2B E-commerce Trends for 2020/2021